Through integrated stevedoring, infrastructure and logistics services, Flinders Port Holdings connect South Australian businesses to each other and to the world.

Flinders Port Holdings own and operate Flinders Adelaide Container Terminal as well as the six key regional ports of Port Giles, Port Lincoln, Wallaroo, Port Pirie, Klein Point and Thevenard.

Through integrated stevedoring, infrastructure and logistics services, Flinders Port Holdings connect South Australian businesses to each other and to the world.

Flinders Port Holdings own and operate Flinders Adelaide Container Terminal as well as the six key regional ports of Port Giles, Port Lincoln, Wallaroo, Port Pirie, Klein Point and Thevenard.

We also provide integrated supply chain solutions through Flinders Logistics and Flinders Warehousing and Distribution. Beyond ports and logistics, we deliver hydrographic survey services through HydroSurvey Australia.

7

1,795

280

24

200

Contributions

7

1,795

280

24

200

Contributions

Flinders Ports is South Australia’s leading port operator with seven ports located at Port Adelaide, Port Lincoln, Port Pirie, Thevenard, Port Giles, Wallaroo and Klein Point. We are committed to the ongoing investment in port infrastructure and equipment. Our status as a private port operator gives us the opportunity to reinvest in the business and the flexibility to ensure that capital expenditure is properly targeted – maximising the benefit for our valued clients and communities.

Flinders Ports is South Australia’s leading port operator with seven ports located at Port Adelaide, Port Lincoln, Port Pirie, Thevenard, Port Giles, Wallaroo and Klein Point. We are committed to the ongoing investment in port infrastructure and equipment. Our status as a private port operator gives us the opportunity to reinvest in the business and the flexibility to ensure that capital expenditure is properly targeted – maximising the benefit for our valued clients and communities.

Flinders Adelaide Container Terminal is a world class facility able to facilitate Panamax and Post-Panamax class vessels. FACT has three state-of-the-art Post-Panamax cranes, delivering efficient supply chains for our shipping line clients. We also boast an in-house crane simulator training facility at the Terminal further extending our strong safety culture which allows us to deliver greater efficiency to our clients. The terminal is also pioneering AI supported container movement optimisation, further strengthening the ability to quickly and efficiently move containerised cargo through Port Adelaide.

Flinders Adelaide Container Terminal is a world class facility able to facilitate Panamax and Post-Panamax class vessels. FACT has three state-of-the-art Post-Panamax cranes, delivering efficient supply chains for our shipping line clients. We also boast an in-house crane simulator training facility at the Terminal further extending our strong safety culture which allows us to deliver greater efficiency to our clients. The terminal is also pioneering AI supported container movement optimisation, further strengthening the ability to quickly and efficiently move containerised cargo through Port Adelaide.

Flinders Warehousing and Distribution is an innovative and fully integrated logistics provider conveniently located adjacent to the Flinders Adelaide Container Terminal at Outer Harbor. We specialise in building and supporting efficient, reliable, and cost-effective supply chains. Our tailored solutions, include warehousing, distribution, import and export quarantine services and transport. We also offer services such as container pack/unpack – including heavy and out of gauge (OOG) cargo – storage, distribution, and additional supply chain services to suit your needs. All of our services are offered across our two linked sites at Port Adelaide.

Flinders Warehousing and Distribution is an innovative and fully integrated logistics provider conveniently located adjacent to the Flinders Adelaide Container Terminal at Outer Harbor. We specialise in building and supporting efficient, reliable, and cost-effective supply chains. Our tailored solutions, include warehousing, distribution, import and export quarantine services and transport. We also offer services such as container pack/unpack – including heavy and out of gauge (OOG) cargo – storage, distribution, and additional supply chain services to suit your needs. All of our services are offered across our two linked sites at Port Adelaide.

Flinders Logistics is an industry leading multi-modal logistics provider with facilities at Port Adelaide and Port Pirie. Specialising in supply chain logistics for the mining and oil exploration sectors, we have pioneered containerised bulk exports while having also built up a proven track record in safe and efficient unloading of bulk cargoes. By focussing on innovation to drive up standards in safety and environmental management, we are improving efficiency in stevedoring and logistics services – from pit-to-ship.

Flinders Logistics is an industry leading multi-modal logistics provider with facilities at Port Adelaide and Port Pirie. Specialising in supply chain logistics for the mining and oil exploration sectors, we have pioneered containerised bulk exports while having also built up a proven track record in safe and efficient unloading of bulk cargoes. By focussing on innovation to drive up standards in safety and environmental management, we are improving efficiency in stevedoring and logistics services – from pit-to-ship.

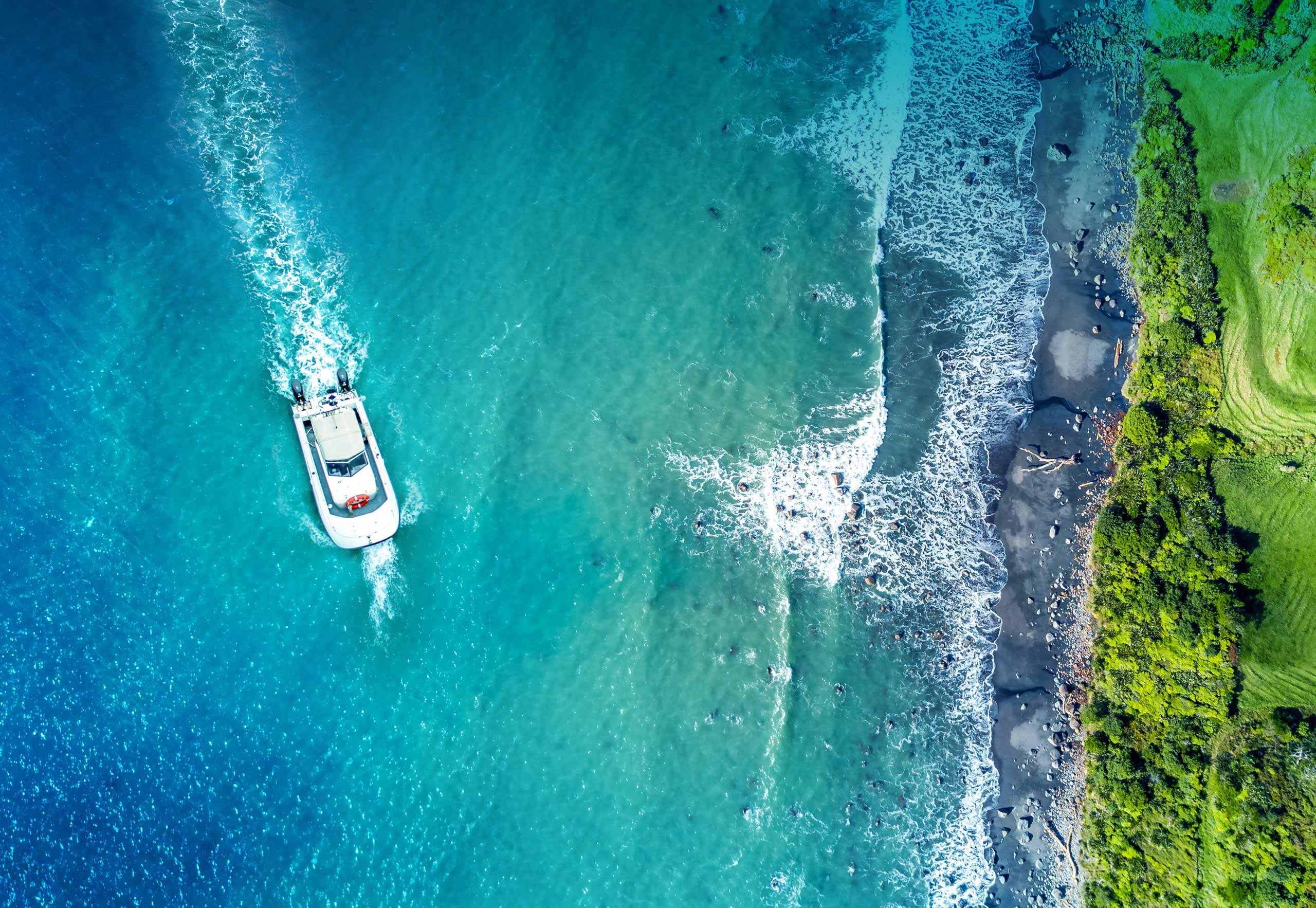

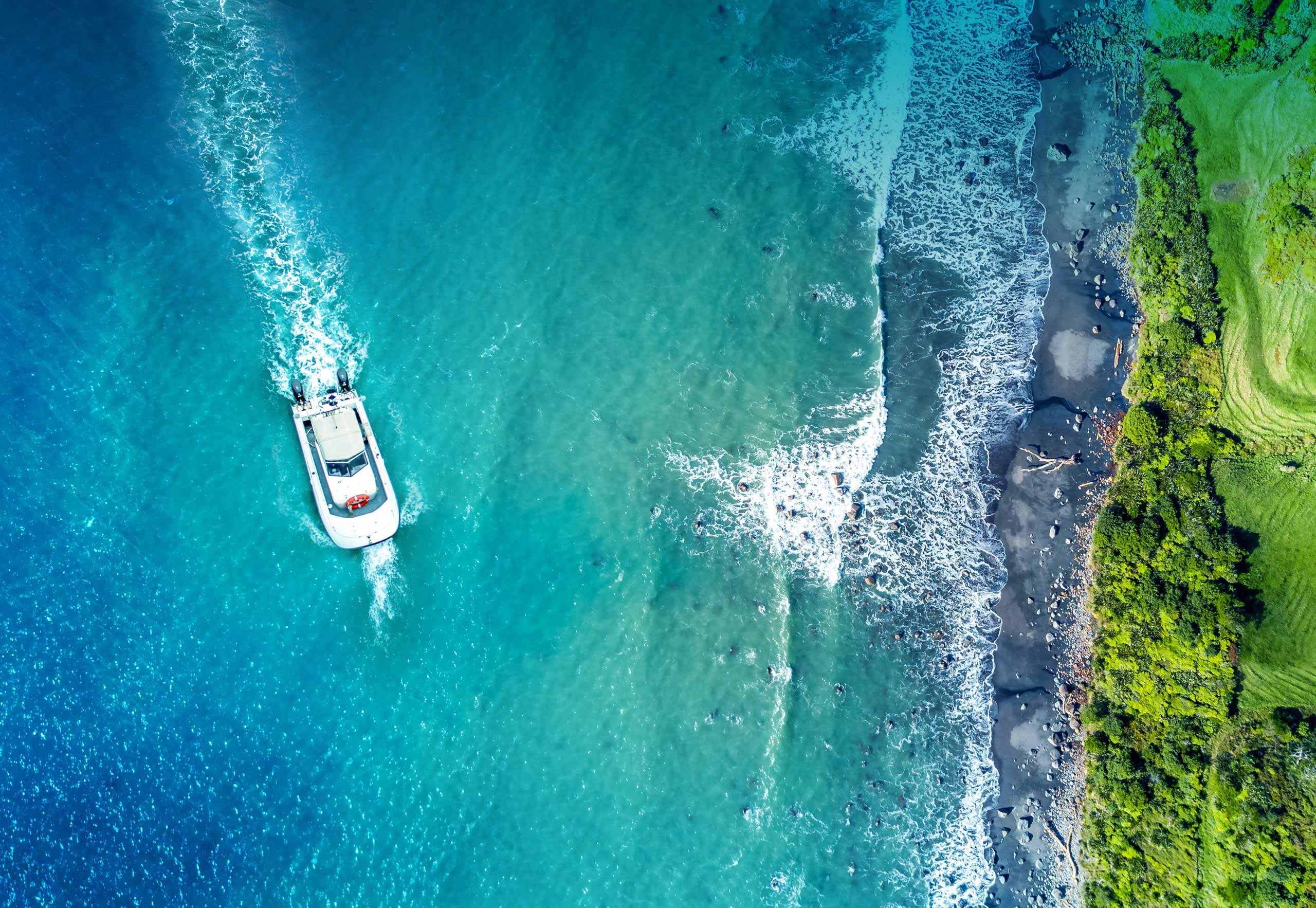

Using our own vessels and the latest technology, our team delivers hydrographic and tide services for a range of private and public sector clients. Our accredited hydrographic surveyors provide expert hydrographic surveys of the seabed, navigation channels, berths and inland waterways. The company also maintains and calibrates tide gauges and manages tide data reporting for the State of South Australia.

Using our own vessels and the latest technology, our team delivers hydrographic and tide services for a range of private and public sector clients. Our accredited hydrographic surveyors provide expert hydrographic surveys of the seabed, navigation channels, berths and inland waterways. The company also maintains and calibrates tide gauges and manages tide data reporting for the State of South Australia.